Everything You Need to Know About Printing and Publishing a Board Book

You might wonder why there isn’t a board book option on Amazon KDP or IngramSpark the way there is for paperback or hardcover. When you look into it, you quickly find that board books manafatures almost always come with a minimum order quantity.

Why there isn't an option for Boardbook Print on Demand

The most common misconception is that a board book is just a regular book with thicker paper. In reality, a board book is built more like a product than a book, at lease for mass production level.

For standard book, Print of Demand (POD) is very popular. It is a good way to test out the market. However, it only exist for hardcover and paper back. The reason is that POD printer simpeliey the step, use glue spine instead my swen spine, and the demand is high eought to make it doable.

Compare to boardbook, it invole many production steps, and almost all of them come with a fixed setup cost. And as the POD boardbook demand is not as high, so most POD printer dont offer this option.

How a board book is made

There are two common ways to make a board book. Some manufacturers mount printed paper onto a pre-made rigid board. We use another very common method: we print on thick cardstock and bond two sheets together to form each page.

-

File checkAs the starting of our workflow, we review your files to make sure the trim size, bleed, and page order are set up correctly. This helps avoid white edges, cut-off text, or page order issues.

-

Print on thick cardstock We print on 350gsm cardstock. We print single sided and use a spread layout so your artwork looks continuous across facing pages.

-

Lamination for durability We laminate the printed sheets to protect the surface. This makes the pages more durable, more water resistant, and easier to wipe clean, which is important for kids books.

-

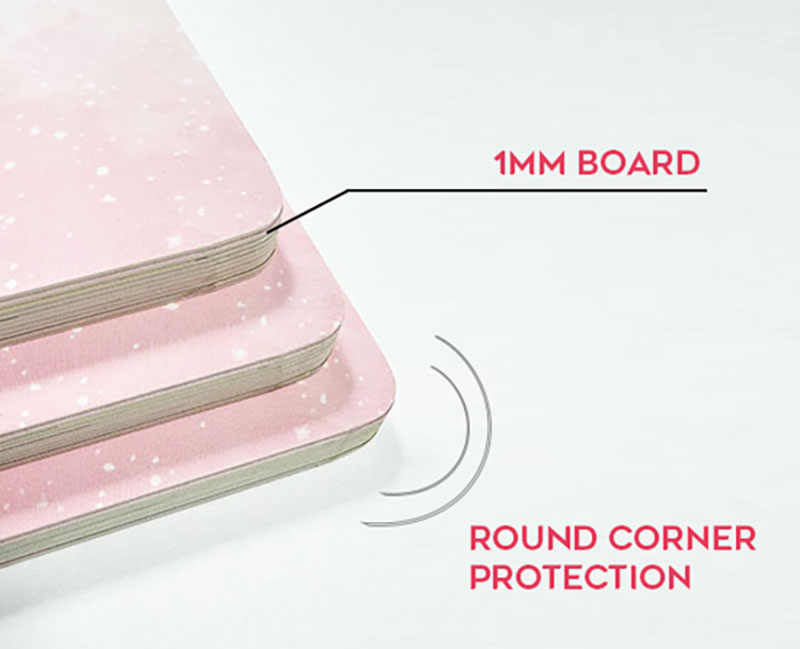

Bond two sheets into one “board” page We apply adhesive with glue rollers, align two sheets back to back, then run them through press rollers. After bonding, each finished page is about 1mm thick, which is a common standard thickness for children’s board books.

If you want a thinner or thicker page, we can adjust the page thickness by choosing a different paper thickness. The process stays the same, but the final “board” page will feel lighter or more rigid depending on your goal.

-

Cut to shape and round the corners We use a cutting die to trim pages to the final size and shape, then round the corners for safety and a clean finish.

This is a mass production factory workflow, and as you can see it involves many steps, and almost every step has its own setup and make ready cost.

Physical sample vs production run

Many first-time authors ask for a physical sample before moving forward. That is a smart step, but it is important to understand what kind of sample you are getting.

If you ask a book manufacturer for a “sample,” they may offer a digitally printed sample. This is usually printed on a digital press, then hand bound into a mock-up. It can be helpful to check the overall size, page order, and general look and feel, but it is not the same process as the real production run.

For most large production runs, the final books are printed by offset printing. Offset uses different equipment, different ink behavior, and a different production setup. Because of that, a digitally printed sample may not match the final offset result, especially for color.

If color accuracy is a top priority, the best question to ask your manufacturer is

Can you provide an offset-printed proof or offset sheet sample using the same process as the production run?

We do not offer digitally printed samples for boardbook order. Instead, we offer an offset sheet sample for $120. This sample is produced using the same printing procedure as the production run, which makes it a better option for checking color accuracy before the full board book order goes into production.

Price vs quantity vs size

There are a few factors that directly affect the cost of a board book. The two biggest ones are quantity and size.

1. Quantity

Quantity is usually the biggest factor. A board book involves many production steps, and most of those steps have a fixed setup and make-ready cost. When you print more copies, that fixed cost gets spread across more books, so the unit price drops quickly. That’s why there is often a noticeable difference between 250, 500, and 1,000 copies.

2. Size

Size affects cost mainly because it can change how many press setups are required. In offset printing, each unique press sheet needs its own set of CMYK plates, so fewer unique sheets usually means fewer plate sets and less make-ready time.

To understand why size matters, it helps to know how pages are arranged. We lay out your page spreads on large press sheets, often around 1194mm x 889mm, similar to a large poster sheet. The goal is to fit as many spreads as possible on each sheet.

If the size fits efficiently, we can often reduce the number of unique sheets needed for the book. That directly reduces the number of plate sets and setups, which is where a big part of the cost comes from. Paper waste matters too, but the plate and setup work is usually the bigger cost driver.

| Quantity (20P) | 5 x 5 Unit Price | 6 x 6 Unit Price | 7 x 7 Unit Price | 8 x 8 Unit Price |

|---|---|---|---|---|

| 250 | $3.98 | $4.66 | $4.82 | $5.61 |

| 500 | $2.23 | $2.21 | $2.92 | $3.53 |

| 1000 | $1.66 | $1.85 | $2.02 | $2.54 |

5 x 5, 6 x 6, 7 x 7, and 8 x 8 are four of the most common board book sizes. If you want to get the pricing and shipping, you can use our cost calculator.

What quantity a first-time author should order

From a printer’s point of view, the “right” first quantity isn’t about chasing the lowest unit price. It’s about matching your inventory to your real sales plan, so you don’t end up with boxes sitting for years.

Here’s the pattern I see over and over with first-time board book projects.

The safe starting point is the lowest quantity you can confidently sell through

If this is your first children’s book and you’re still learning how you’ll sell it, a smaller first run is usually the smartest move. You’re buying real inventory, but you’re also buying clarity. You learn how parents react to the book, what price point works, which channels actually move units, and what adjustments you want before you commit bigger.

That’s why many first-time creators start with a conservative first run and plan a second run if the book proves itself.

Real-world experience from other creators

One board book creator,

u/LindsayKellarMadsen,

shared a practical lesson from a large run. They funded a first print run of 3,000 copies through a crowdfunding campaign and still had about 1,000 left after two years. Their takeaway was that for a first book, it can be safer to aim closer to 1,000 while you learn the ropes of marketing and distribution.

Another experienced self-publisher, u/BarelyOnTheBellCurve, pointed out a cost that first-time authors often miss. It is not just the print bill. Once you hold inventory, you may also be paying for shipping and, depending on your fulfillment setup, ongoing warehousing and fulfillment fees. Those costs are why printing more copies only makes sense when you have a clear plan to sell through them.

A simple quantity guide that works in real life

- 250 copies Best when you are testing demand and selling mostly direct. It keeps inventory risk low, and it gives you room to adjust for your next run.

- 500 copies A strong middle ground if you have a real plan to sell consistently, such as local events, school visits, a partner audience, or steady online traffic.

- 1,000 copies Best when you have proof of demand, like preorders, bulk interest, or a reliable sales channel that can move volume.

- 3,000 copies and up Usually for established demand or funded campaigns. It can absolutely work, but it’s a serious inventory commitment.

My printer advice

If you’re not sure, start with a quantity you can realistically sell in 3 to 6 months, then reprint. A slightly higher unit price is often cheaper than long-term storage and unsold inventory.

Board book testing and safety

If you plan to sell your board book in the U.S., it’s helpful to be aware of how safety rules are discussed for children’s products. Some printed items are treated as “ordinary books,” but board books can be viewed a bit differently depending on the age group and how the book is designed.

The CPSC explains that there is a testing exemption for “ordinary books” and “ordinary paper-based printed materials.” In simple terms, an ordinary book is a traditional book printed on paper or cardboard with standard inks or toners and finished in a normal way, mainly for reading or educational use.

However, that exemption does not include items designed or intended for children 3 years old or younger, and it does not include books with “inherent play value.” That’s one reason board books could be treated differently than a standard paperback.

From our manufacturing side, the paper and inks we use are standard materials that meet the applicable production standards in our printing region in China. We do not provide testing services or compliance certification. If your sales channel or retailer requires formal testing or documentation, the best approach is to work directly with a qualified testing lab or compliance professional.