Printing & Production Techniques

Offset Printing

Offset lithography, also known as “offset printing”, is a popular printing technique used to produce a wide range of printed materials, such as newspapers, magazines, books, packaging, and brochur...

Digital Printing

body { font-family: Arial, sans-serif; line-height: 1.6; max-width: 800px; margin: 40px auto; padding: 0 20px; color: #333; } h1, ...

Gravure

Gravure printing is a high-speed, high-quality printing process that uses a metal cylinder engraved with images or text, which is then directly pressed onto the substrate. It is commonly used to print...

Letterpress

Letterpress is one of the oldest printing techniques and the contents printed by it are touchable because of its means of printing. It inks the raised letters or images and manually presses it onto th...

Flexography

Flexography is a relief printing technique that uses flexible rubber or photopolymer plates to press the inks onto the substrates, these inks are fast drying due to its mechanism and it usually widely...

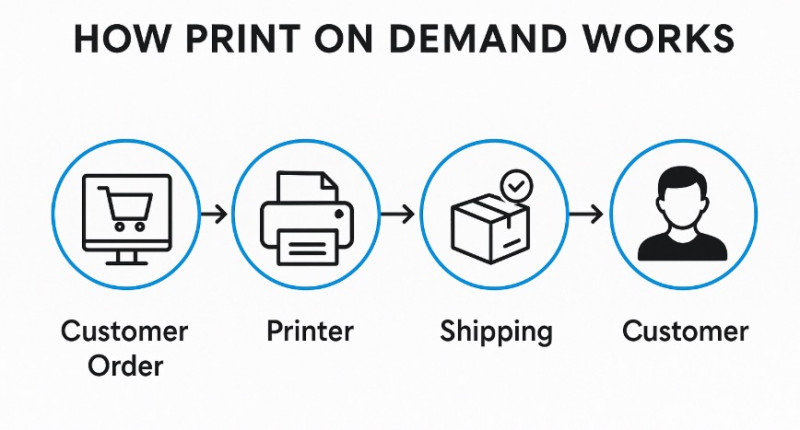

Print-On-Demand

Print on demand meaning the items will only be printed or produced after customer placing their orders, which it allows customers to individualize the the designs, quantities and other factors of thei...

UV Coating

UV coating is a liquid coating that is applied on the printing materials and cured with UV light, it is use to add a shiny or matte layer on the business cards or brochures to make them look better an...

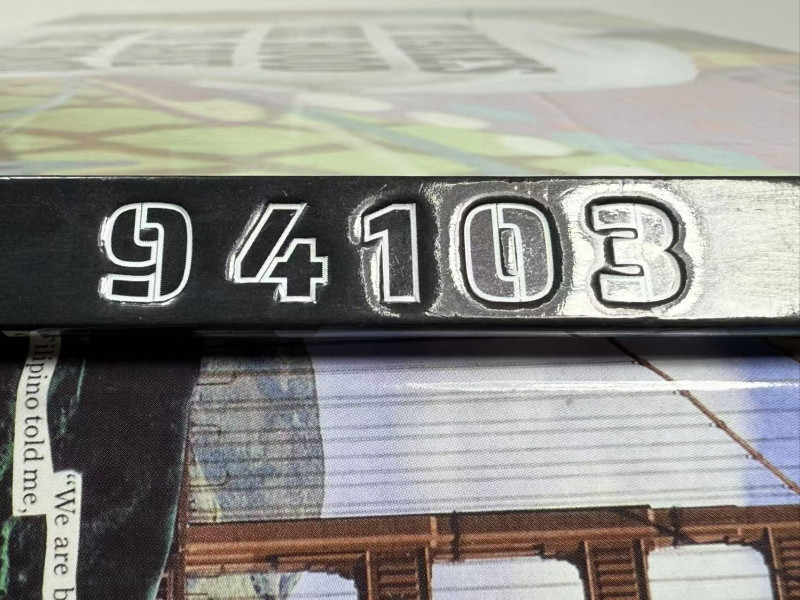

Debossing

Debossing is the opposite of embossing. Instead of raising the design, it presses the image or text into the surface to create a recessed effect. Debossing gives a subtle, sophisticated look and is ...

Foil Stamping

Foil stamping is a printing technique that using heat and pressure to press a thin layer of metalic or pigmented foil onto the surface of the printed material. This kind of technique can create a refl...

Screen Printing

Screen Printing is a printing method that pushes the ink through a mesh screen onto the surface below. It often used for textiles, posters, and packages with bold colors Screen Printing FAQ Ho...

Varnish Coating

Varnish coating is a clear liquid applied to printed materials for protection and decoration purposes. It consists with three different style; glossy, matte, or satin, which enhances the look of the p...

Laser Cutting

Laser cutting uses a high-powered laser beam to cut or sculpture precise shapes and patterns on materials like paper, wood, or acrylic. This technique is best for products that require complex and det...

Lamination

Lamination means putting a thin plastic film on the printed materials to improve durability and appearance. It protects against moisture, fingerprints, and tearing to make sure the product can adapt i...

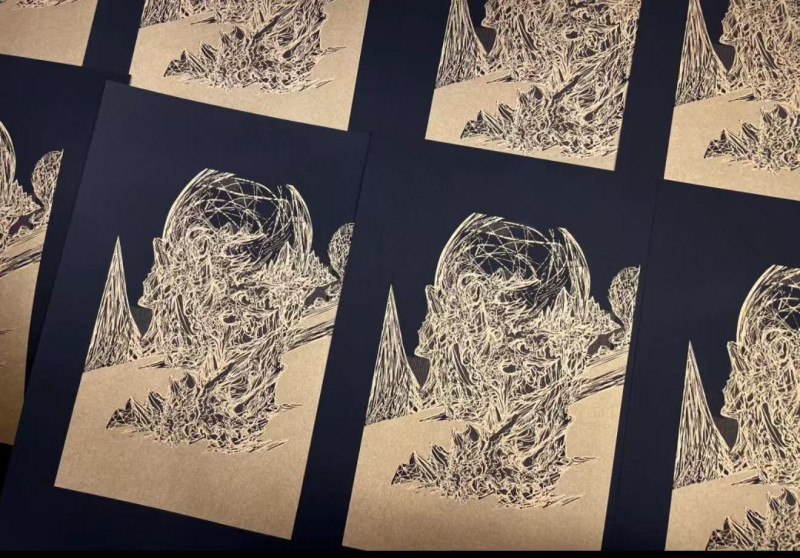

Metallic Ink Printing

Metallic ink contains tiny reflective particles that provide a shining metallic finish to the printing designs. It’s used to enhance logos, titles, or accents on packaging, invitations, and business...

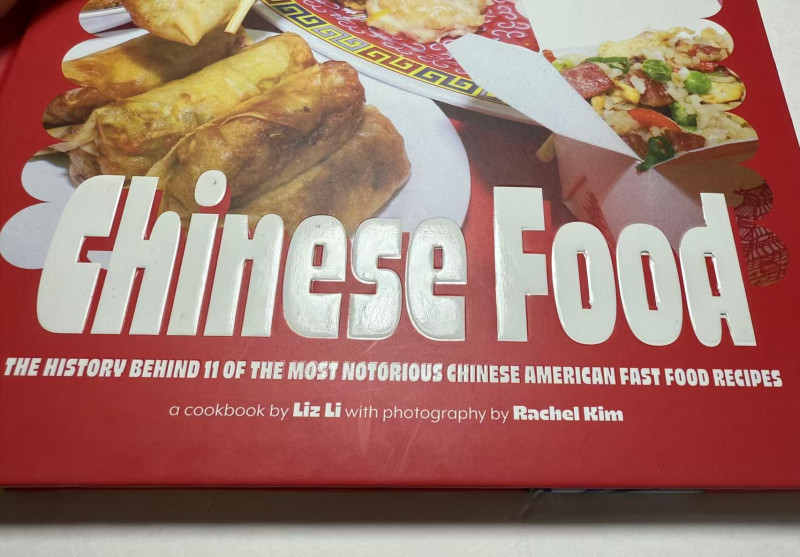

Embossing

Embossing is a printing technique that uses a metal die to press certain parts of the paper, such as text, logos, or images, so they raise above the surface. This creates a stylish look and a tactil...

Spot UV

Spot UV is a glossy coating applied to specific areas of a printed piece, enhancing contrast and focus with shine, it usually applied on logos or text for emphasis.

Raised UV

Raised UV adds a textured, elevated glossy finish to selected areas. It provides a tactile, 3D feel and visual depth, ideal for enhancing branding elements and luxury print materials.