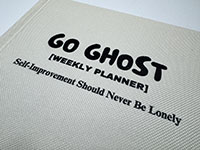

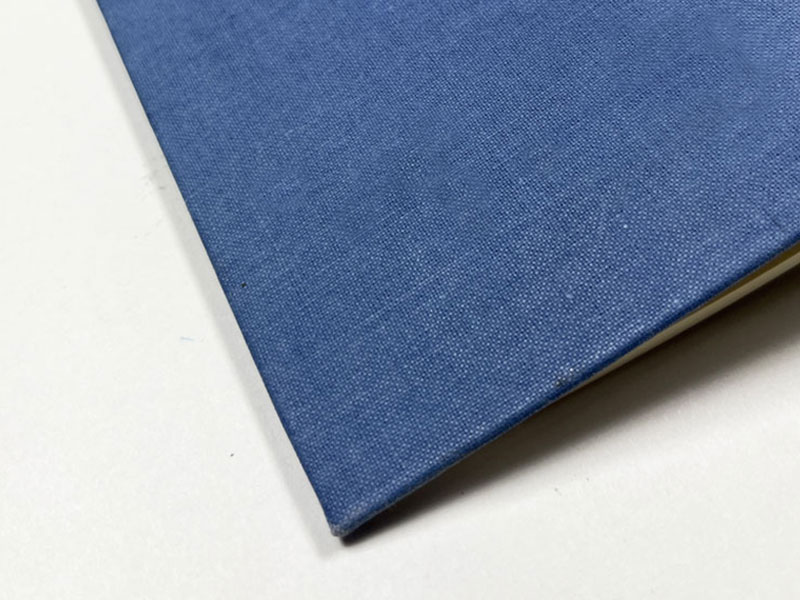

Cloth/Linen Book Cover

Add-On Pricing

Standard Combination for Cloth Book Covers

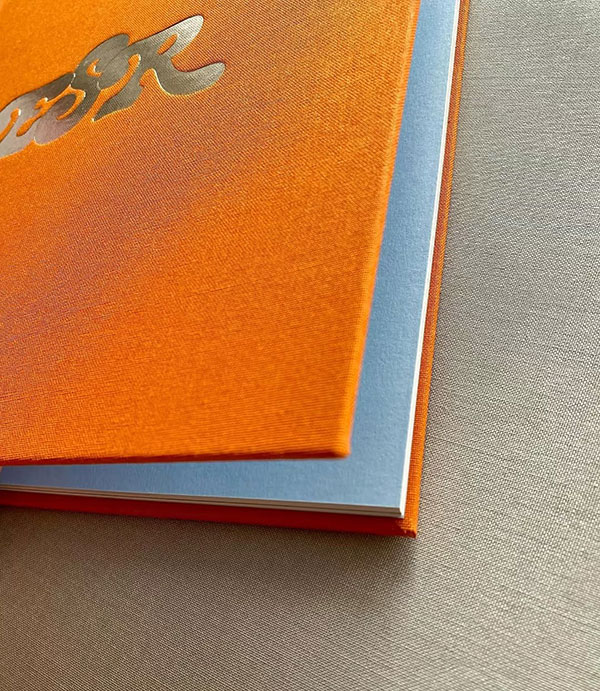

Cloth book covers are often crafted with a specific set of features to balance durability, style, and protection. This standard combination, which you’ll often see in the market, includes a cloth cover, decorative techniques like foil stamping or debossing, and a dust jacket.

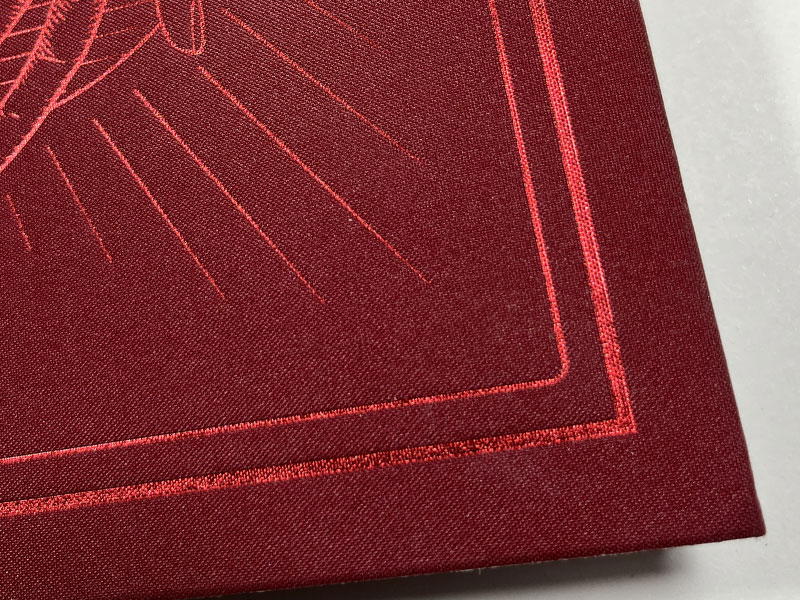

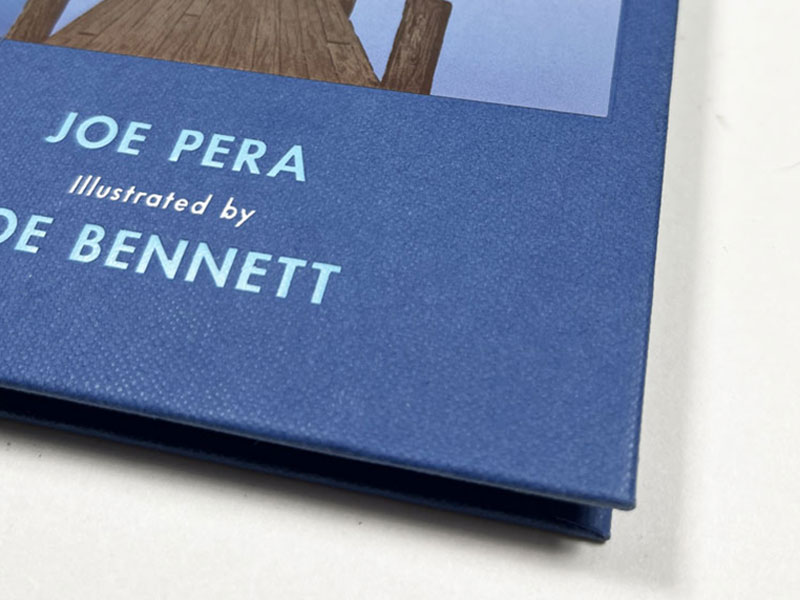

- The Cover Wrap: A specific type of book cover material will be used, such as flax linen, cotton-based cloth, or synthetic fibers. These high-quality materials can withstand frequent handling and are pre-handled with backing to prevent glue from seeping through.

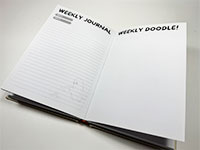

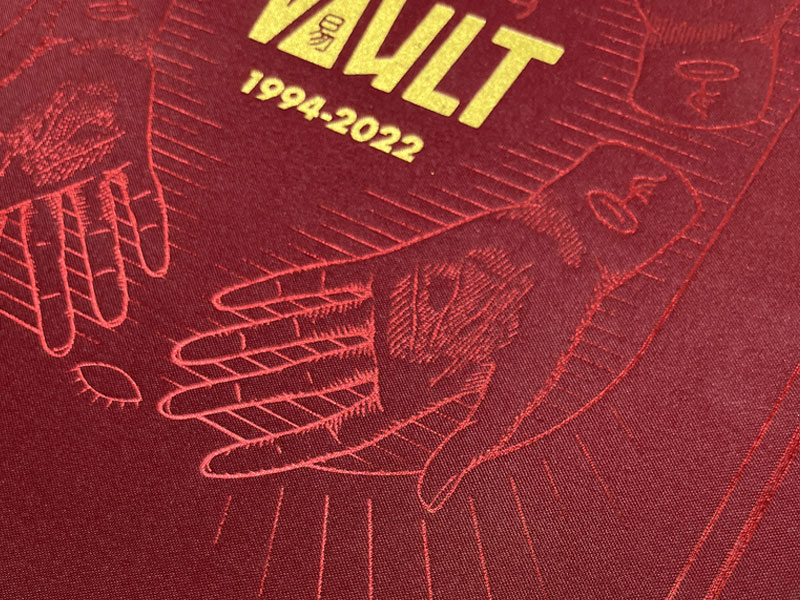

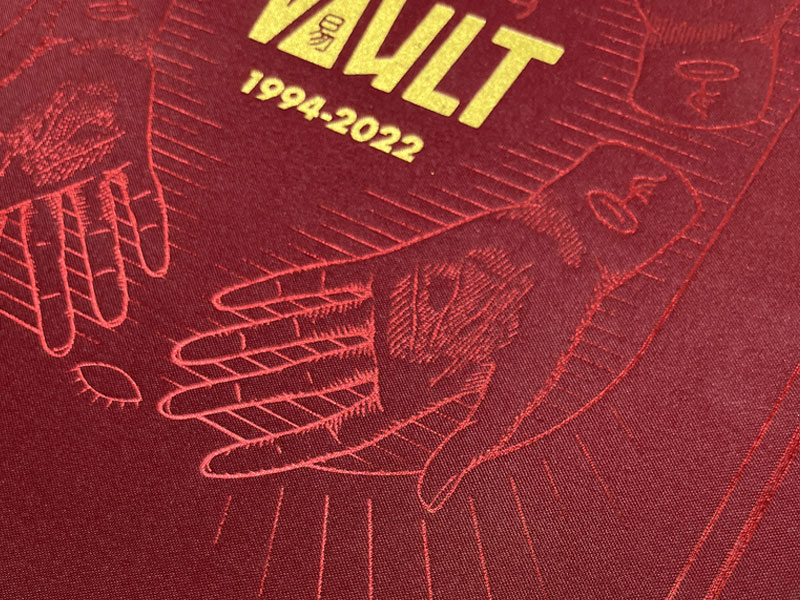

- Decorative Techniques: With modern printing techniques, we can actually print full color on cloth-like materials. However, the most common decorative techniques are still foil stamping or debossing, which are often applied to the front cover and spine.

- Dust Jacket: A dust jacket, often made of printed paper, wraps around the cloth cover to protect it from dust, scratches, and damage. It also allows for colorful artwork, author details, or summaries to attract readers. Many dust jackets are removable, preserving the cloth cover’s clean look underneath.

How our Pricings Work

Cloth is an add-on. Simply determine the book cost, then calculate the cloth cover cost using the calculator above. Add other add-ons, such as foil stamping, debossing, or a dust jacket, to get the final quote.

Ordering an Sample

We’ve made ordering a physical sample easy by offering a flat rate for most books, as long as they aren’t oversized or have a couple hundred pages. This rate includes shipping to most U.S. addresses. The sample book will be printed with a digital printer, different from the actual offset production run, but we’ll bind it with the cover materials you selected. View more details on our physcial proof page.

| Book with Cloth | $120 |

| Foil/Deboss | $60 per Color |

| Dust Jacket | $20 |

How We Make Book with Cloth Covers

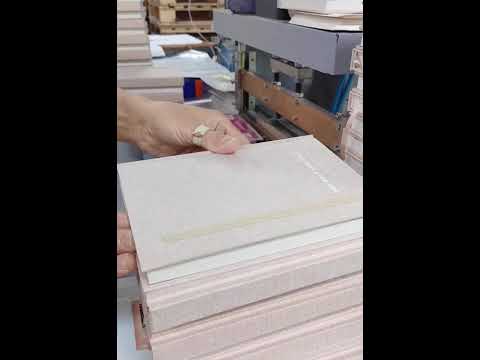

As a printer and binder, we craft our cloth book projects using premium linen fabrics that must be high-quality to withstand handling and effectively absorb glue evenly. We cut these fabrics to size and bond them to the binder’s board using archival PVA glue.

The cloth is carefully wrapped, aligned, and then pressed in a hydraulic press to ensure a smooth, durable finish, with each cover inspected to ensure a high-quality finished product.