Offset

Offset lithography, also known as “offset printing”, is a popular printing technique used to produce a wide range of printed materials, such as newspapers, magazines, books, packaging, and brochures. The reason it is called “offset” is because the image is first transferred (or "offset") from a metal plate to a rubber blanket, and then onto paper.

This extra step helps create cleaner, sharper images and protects the plates from wearing out quickly. It’s the top choice for large quantity printing tasks and projects that demand high consistency and image quality.

Offset Printing FAQ

What is offset printing?

Offset printing uses plates to transfer ink onto a rubber blanket, then onto the paper, ideal for high-volume jobs that require 1,000 copies or above.

Is offset printing good for short runs?

No, it’s more cost-effective for large print runs. For quantities under 500 copies, the setup costs make offset less economical compared to digital printing.

How long does offset printing take?

Offset printing usually takes 3-7 days to complete. This timeframe includes preparing custom plates, setting up the press, running color calibrations, performing test prints, and allowing time for drying (especially with coated papers). All of these procedures are necessary to ensure accurate and high-quality results.

Heidelberg Offset Printing Machine

Heidelberg 5+1 Offset Printing Machine

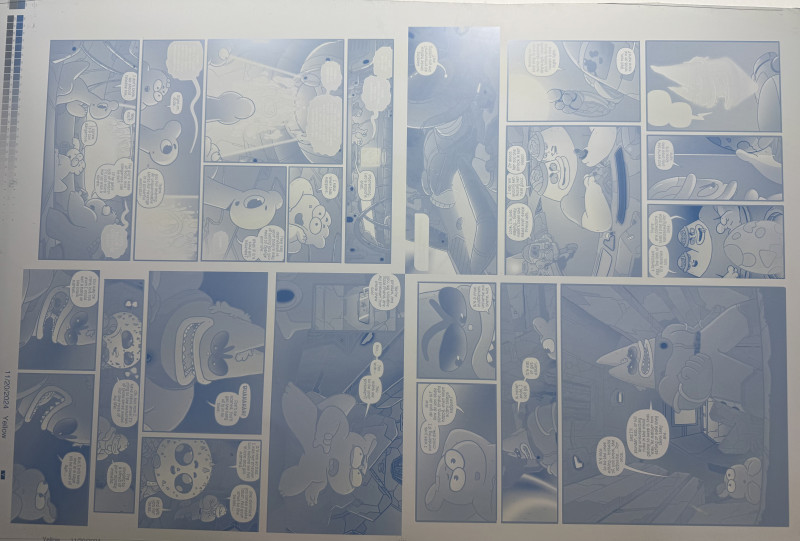

Cyan Offset Plate